Challenge

Certain geological formations will force the drill string in unwanted directions. Other times it is simply the corebarrel setup and bit selection that creates deviation. The drill platform and or drilling style of the driller can also affect deviation. Because there are so many uncertainties it can be difficult to aling drills to take into account the natural deviation. As a result restarting boreholes multiple times may be required to attain the target.

Solution

TECH Directional Services closely tracks boreholes to detect unwanted natural deviation by utilizing the DeviGyro system. Once it is determined an intervention of the boreholes trajectory is necessary, Technicians react with the use of our industry leading Directional Drilling Package.

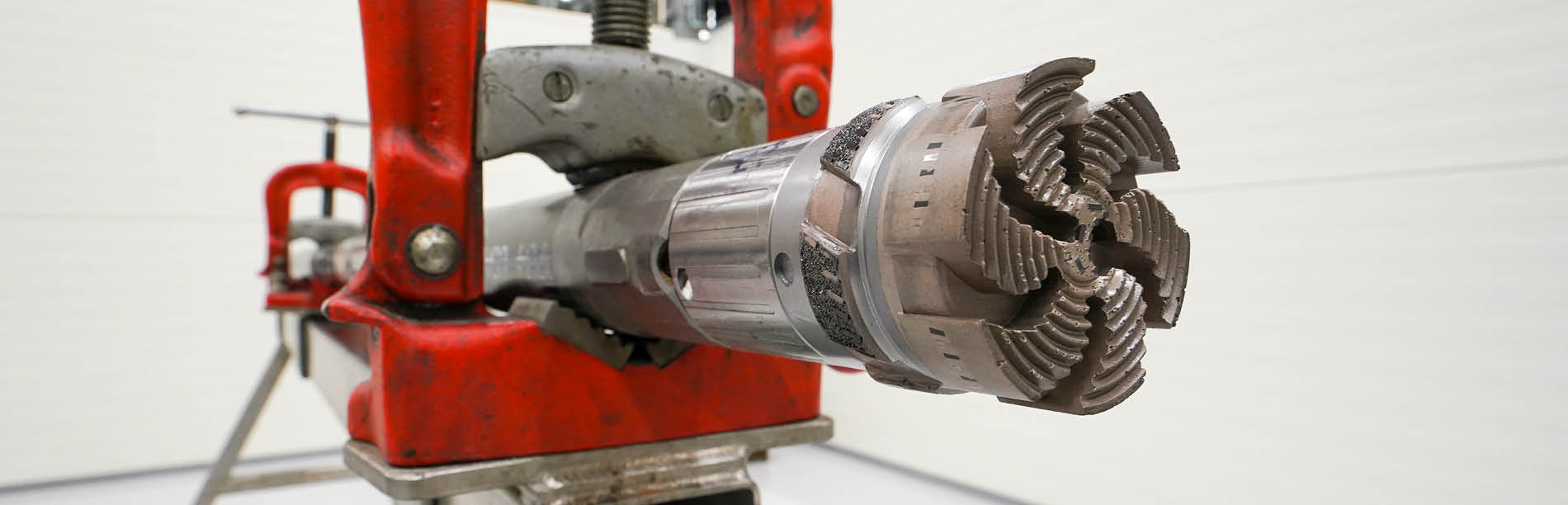

This package includes one DCD barrel (DeviDrill), one non-coring directional barrel (DeviDrill RSS) and DeviGyro system for accuracy. The DeviDrill allows clients the option of gathering Geological information as steering occurs by collecting a core sample. If this information is unnecessary and speed is the goal, the DeviDrill RSS system will be used to speed up production up to 5x.

Benefits

- Full control over the hole trajectory at all times

- Always intersect the target with high accuracy, even at great depths

- No need to restart boreholes

- Always collect the data you are looking for the first time

- Quick realiable steering