Challenge

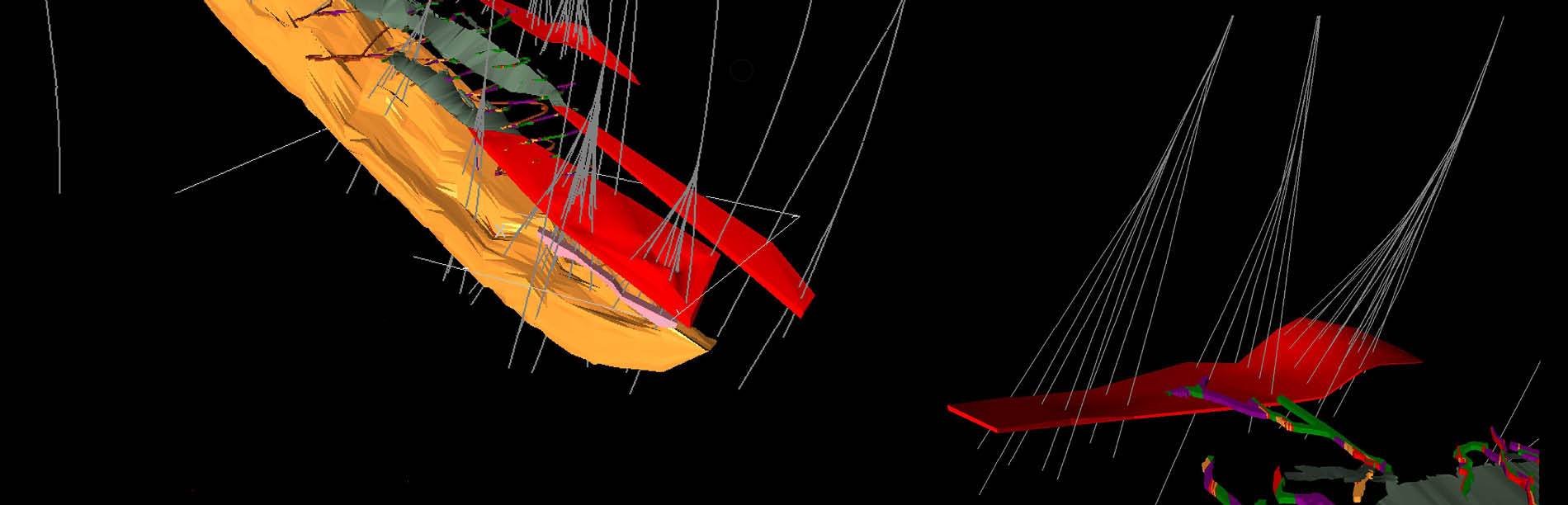

In order to define a resource and increase estimates, infill drilling between intercepts of the orebody is required. Using conventional methods it is extremely time consuming and difficult to achieve the spacings. The deeper the resource is, it can become next to impossible to complete in a timely manner. Finding the proper alignment to hit these targets is also problematic. This is most common in an underground environment where you are limited to where drilling platforms may be setup.

Additionally, a boreholes natural deviation plays a big role in how difficult it may be to achieve the proper spacing. In most cases restarting holes multiple times is required to achieve definition of the resource costing more time and money.

Solution

TECH Directional Services plans your delineation program providing the most effective drilling solution. Once approved technicians mobilize to site with our industry leading directional drilling package. Once on site they will follow the program closely and steer boreholes as required.

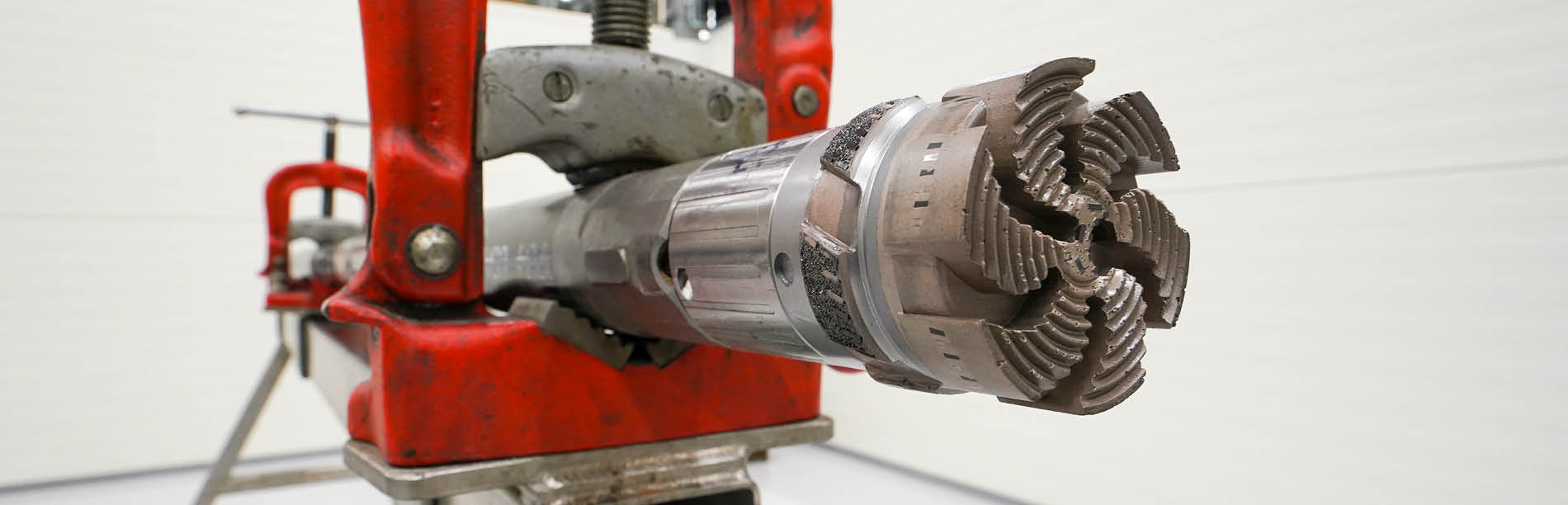

This package includes one DCD barrel (DeviDrill), one non-coring directional barrel (DeviDrill RSS) and DeviGyro system for accuracy. The DeviDrill allows clients the option of gathering Geological information as steering occurs by collecting a core sample. If this information is unnecessary and speed is the goal, the DeviDrill RSS system will be used to speed up production up to 5x.

Benefits

- Significantly reduce the time required to complete a drilling program

- Ensure the target and spacing is always reached with the required accuracy

- Experts with 30+ years and 500,000m of directional core drilling experience

- No additional mud pumps or drill strings required

- Core in directional sections

- Low water consumption

- All necessary equipment in small start package

- Fits directly on N-size drill string

- High penetration rate in hard rocks

- Easily adjustable dogleg

- Higher dogleg used due to smoother curve

- Drill string rotation also during steering